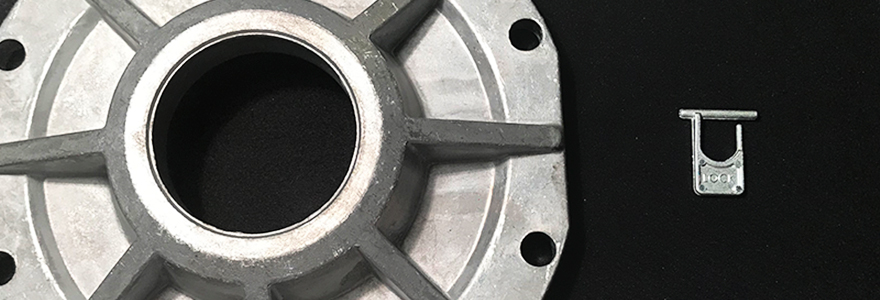

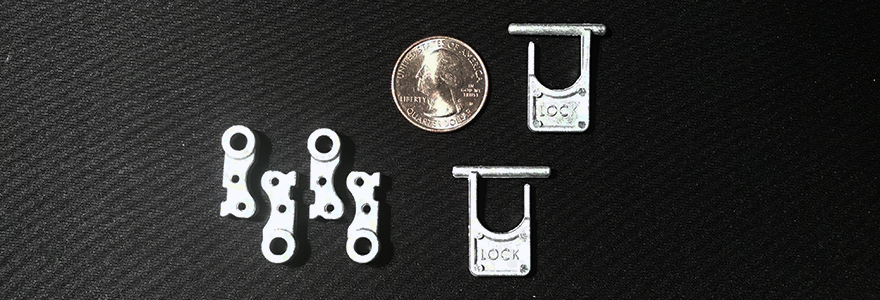

Anderson Die Casting originated in 1953 as a die cast manufacturer specializing in zinc and expanded in 1985 with aluminum to create lighter die casts. Today we manufacture parts with many materials including ZA alloys and specialty alloys. With hard work, outstanding quality, and dependable service we have successfully expanded our facility and our manufacturing capabilities.

In addition to outstanding growth in our die cast department, our secondary machining operations have continued to grow to meet the varied needs of our customers, including: drilling, tapping, turning, boring, milling, sanding, vibratory finish, and more.

All die casting is done with special attention to pollution prevention to protect the environment. Anderson Die Casting has state of the art water evaporator systems to recover all solids. The quality of our tooling and machines are continually enhanced here at Anderson Die Casting, not only for our customers but the safety and protection of our employees.

1

1 2

2 3

3 4

4